Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the Global Website

We have detected that you may prefer the Global site. Please use the language dropdown above to change your selection if required.

Modern regenerative side or end port furnaces as well as recuperative furnaces profit from a stable, controlled combustion process. Such a stable and precisely controlled process will result in improved furnace lifetime as well as optimum, efficient fuel consumption. Energy saving up to 2% can be achieved which will result in a fast return on investment. The glass melting process will also profit from a stable furnace combustion space environment.

Keywords:

To understand the principle of excess of air control we first need to understand how the combustion in a regenerative glass furnace is normally controlled.

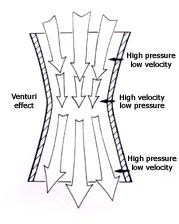

The combustion air flow is normally controlled by a frequency inverter controlling the fan’s electric motor or a variable orifice. An inlet air venturi will provide a combustion air flow value that needs to be normalized (Nm3) by compensating the venturi measurement by the environmental air temperature and pressure according to Boyle Gay Lussac. Such a compensated venturi air flow measurement is capable of providing a measurement preciseness better than 1% at least, if installed and maintained properly. In many cases we experienced that the combustion air measurement importance was underestimated and in most of those cases the proper equipment was available but badly installed, maintained, or wrong Nm3 calculations were implemented.

Fuel flow (2); oil, natural gas or a mixture of both, is normally well measured and normalized (Nm3, kg or ideally; caloric values) mainly because of the financial value the fuel represents and the importance to balance the fuel consumption against the furnace pull rate. Fuel-consumption/pull is one of the most important bench marking figures in the industry. However, without the availability of a precise caloric value or fuel composition values, it will still be difficult to control the combustion. In other words; the fuel-air ratio would need to represent a precise amount of oxygen molecules needed to oxidize all carbon and hydrogen into CO2 and H2O.

Calculating and controlling the combustion air and fuel ratio, having the precise fuel and combustion air flow parameters would be an easy job to do if there was not what we call “the parasitic air”; air entering or leaving the regenerator and furnace system without being measured by the combustion air venturi. Since the whole regenerator and furnace super structure is built out of refractory bricks, there are obviously minor/major opportunities for air leaking into/out of the system. Also burner purge air needs to be taken into account.

Conclusion: Even if we measure the combustion air at the inlet of the regenerator very precisely, this value doesn’t represent precisely the amount of air available for combustion taking place in the combustion space of the furnace.

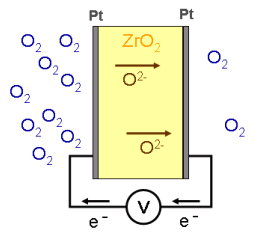

In order to improve the combustion process we need to introduce another measurement which we call the exhaust or flue gas oxygen value (3). For that we would need to have an in situ continuous oxygen measurement as close as possible to the spot after which the combustion process is expected to be finalized, which is in fact inside the combustion air port or regenerator top. It is difficult to measure in those places, which have a very harsh environment; extreme high temperature, and carry over dust along with all kinds of evaporated chemicals. However, a specially designed zirconium-oxide (ZrO2) based probe is able to do such a job. Over the last few years many of these probes have been installed, mainly situated in the crown of the regenerator with a lifetime of approximately 3 years. Such a ZrO2 sensor is normally placed inside the regenerator top, through the crown. In that environment, one side of the sensor is surrounded by the exhaust gases where we like to determine the amount of O2 and the other side of the sensor is surrounded by a small amount of normal purge air – at 20.9% O2.

According to Nernts:

If oxygen is to be measured, using a zirconium ceramic electrolyte and atmospheric air, with pO2 = 0.209, as a reference, this equation simplifies to

pO2 = 0.209 exp(-46.421 E/T)

The equation may be re-arranged, to allow calculation of the emf from a known reference concentration and a measured oxygen concentration:

E = 0.0496 T log(pO2/0.209 )

Since “T” represents the probe temperature there is a type R, S or B thermocouple inside the probe near the ZrO2 sensor.

Eurotherm T2550/2750 system has ZI – Zirconia input module

Input Types: Analogue voltage, Channel 1 – mV (TC), and Channel 2 – 2V (Zirconia probe)

Thermocouple Input Specification (Ch1 ONLY)

Input Range: -77mV to +100mV

Zirconia Input Specification (Ch2 ONLY)

Input Range: -10mV to +1800mV

Next to the measurement of the combustion air forced into the system by the combustion air fan, the precise measured amount of fuel applied to the burners now gives us a third value which represents the amount of oxygen in the flue gas. By having these three parameters we are able to calculate the amount of air which was available for the actual combustion process and the air which entered or left the system without being measured by the combustion air venturi called “parasitic air”.

Both parameters are equally important. The oxygen parameter will be used to trim the amount of combustion air to a value at which the combustion process is near stoichiometric; all reagents are consumed, there is no shortfall of reagent and no residues remain. The other parameter, which shows the amount of “parasitic air”, will be used to safeguard the control system. If this parameter shows unusual behavior it will freeze the ratio tuning algorithm until further inspection of the oxygen probe, combustion air measurement (obstructions) and regenerator and furnace refractory damages.

There are several significant advantages of controlling the excess air. First of all, next to the 20.9% oxygen which we need for combustion, the air also contains 78% nitrogen. Nitrogen is of no use to the combustion process but it has to be heated up to combustion temperature. In fact the combustion process produces, next to CO2, H2O, a lot of very hot useless nitrogen. Like nitrogen, the excess of oxygen represents an efficiency loss and has a nasty side effect as it tends to react with nitrogen at a high combustion temperature resulting in unwanted NOx emissions.

Generally: Using the exhaust flue gas oxygen values coming from the ZrO2 probe to tune the combustion air input to a level at which the air available for combustion, (thus including the parasitic air) together with the applied fuel reaches stoichiometry will increase fuel efficiency and improve NOx emissions.

The glass furnace melting process is very complex and one of the most important control considerations is try to control the process as smoothly as possible. Every fast control action will result in the introduction of unwanted disturbances and side effects. The control of combustion is already disturbed by the inevitable reversal sequence. However, the regenerative principal gives us an efficiency improvement of 80% so there is no way of working around that disturbance.

To improve the efficiency of the combustion process the fuel to air ratio controller has the task of finely adjusting the combustion process as close as possible to a stoichiometric value without the production of CO. Therefore the fuel /air ratio controller needs to take the parasitic air into account which is in fact the difference between the calculated value of air available at combustion and the actual combustion air available at combustion, measured by the oxygen probe in the exhaust. Such a combustion controller normally uses the Lambda value for control which is the ratio of actual air fuel ratio to stoichiometry for a given mixture. Lambda of 1.0 is at stoichiometry. Since parasitic air tends to vary during the time to reversal and will not be the same for both sides of firing, the controller needs to act differently for each firing side and will also need to store the historic values, the once from the time it was controlling that specific side before.

Concluding; although excess of air control is complex, a modern controller or process control system is perfectly capable of managing such a sophisticated strategy. Perhaps the most important part is to educate the furnace operators in order to make them understand how such a control works, to monitor its behavior and judge possible malfunctions. If applied correctly it will provide stable combustion, improved fuel efficiency and reduced emissions of NOx.

Product Selector

Our tool will match the best product to your needs

Launch product selectorContact Us