Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the USA Website

We have detected that you may prefer the United Kingdom site. Please use the language dropdown above to change your selection if required.

Company: Printer of plastic film and food products

Industry: Food & Beverage

Customer Group: End User

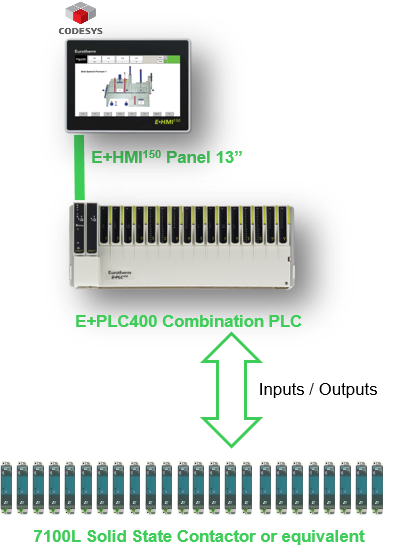

Project / Application: Electrical tracking / tank control

Customer Challenge: Maintain an appropriate viscosity coefficient: by temperature regulations of the paint tanks and printing nozzles

Features, Solutions & Services Provided:

Customer Benefits:

Additional Information:

Product Selector

Our tool will match the best product to your needs

Launch product selectorContact Us