Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the United Kingdom Website

We have detected that you may prefer the Global site. Please use the language dropdown above to change your selection if required.

Flexible Communications Designed for Easy Integration

User data can be exchanged to/from external devices using XML or CSV format. E+PLC products support Modbus communication to enable connection to other instruments and controllers.

Straightforward integration into wider DCS/ SCADA solutions

In addition to Modbus, OPC Server for Windows PC included in CODESYS allows exchange of data from within E+PLC and 3rd party devices, for example from HMIs or process data logging programs.

Ethernet Based Protocols Enable Integration into IIoT/Industry 4.0 technologies and 3rd party devices

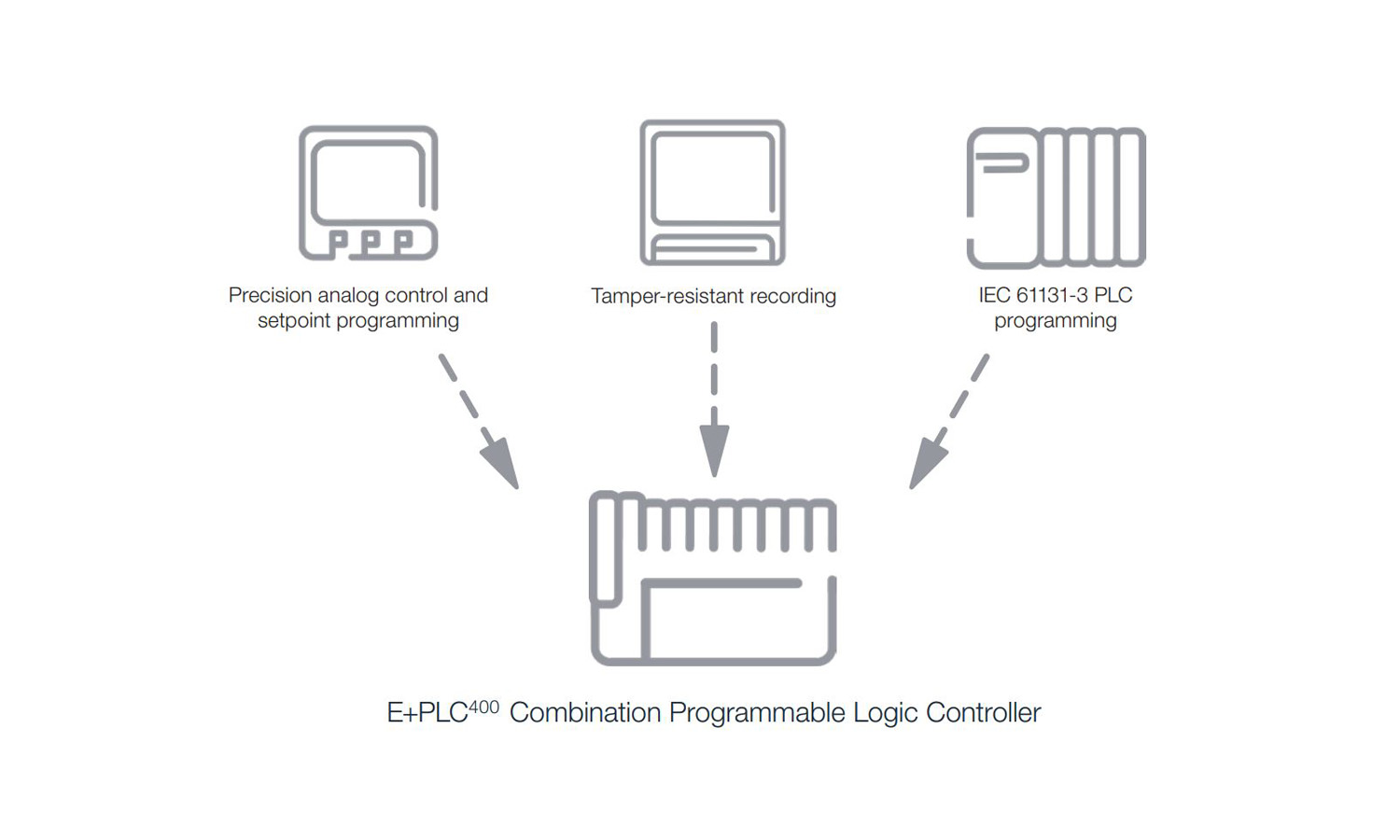

An open PLC designed to offer control and

recording… easily

The E+PLC solution is an open standards based PLC

platform combined with decades of knowledge in precision

PID control and tamper-resistant recording, packaged

in easy to use function blocks and libraries for fast

implementation.

Accurate measurement enables better

process performance

Precision control and setpoint programmer

both enable efficiency optimization

Tamper-resistant recording aids compliance to

industrial regulations and quality standards

A PLC designed to offer faster integration

Available as a product or fully engineered system

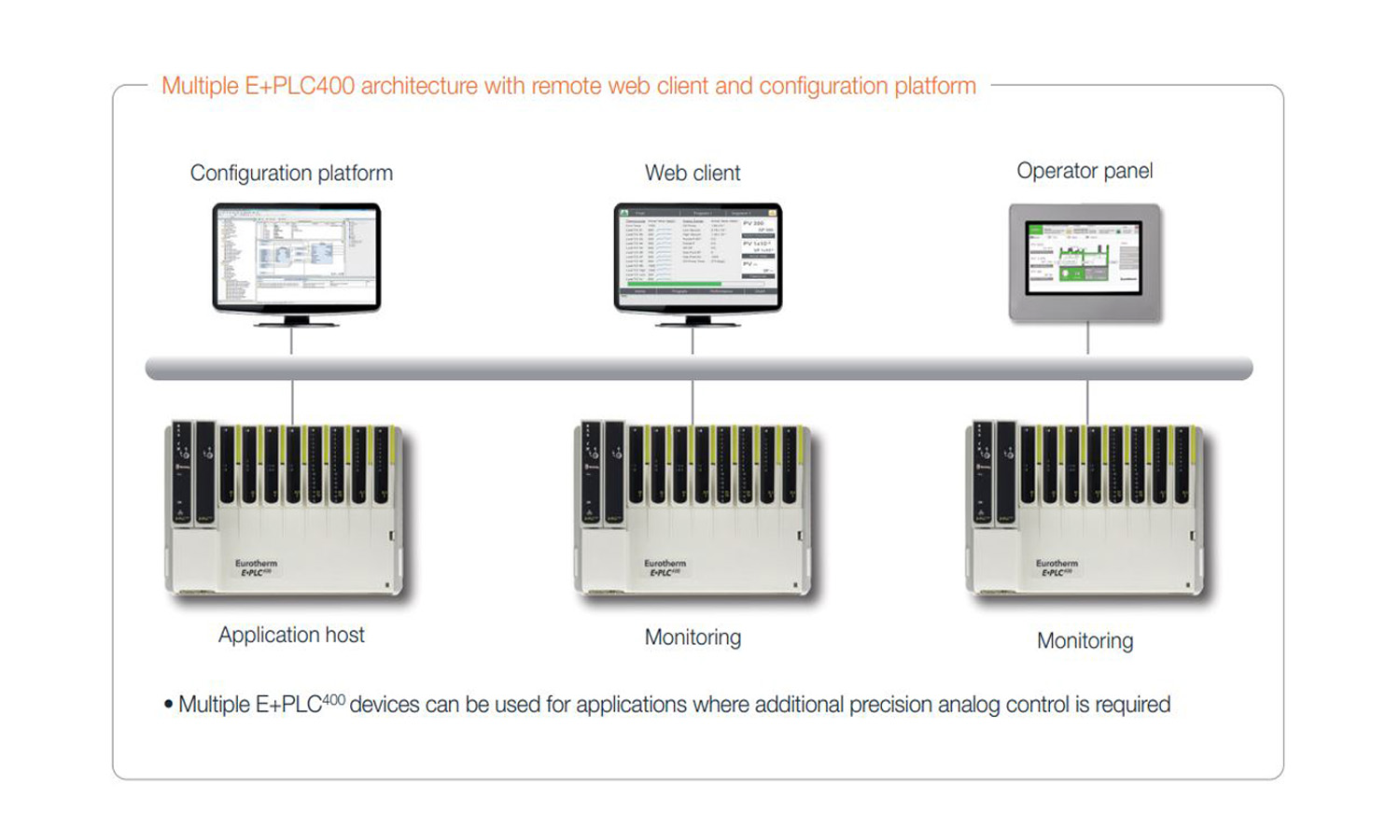

Multiple E+PLC400 Architecture with E+HMI150, Web Client and Configuration Platform

“A customer wanted to increase efficiency by creating batches automatically when orders were entered into their ERP (Enterprise Resource Planning) system. The Eurotherm solution automatically entered data into XML format, where it was ready for processing. The E+PLC regularly copied newly entered data from the enterprise system to its own Batch queue using FTP over Ethernet communications. Automating the data entry process met our customers efficiency requirement by reducing data entry time. Additionally, human interactions and bar code scanners were no longer required, which reduced operator related errors and equipment costs.”

System Integrator Engineer

Product Selector

Our tool will match the best product to your needs

Launch product selectorContact Us